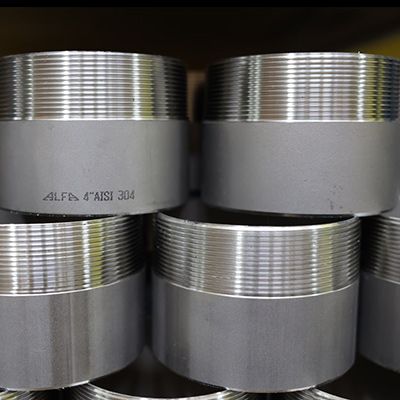

Stainless steel flanges in Chelyabinsk

Flanged connection is one of the most common. It is characterized by strength, reliability and durability. Stainless steel flanges withstand the effects of aggressive media, pressure up to 40 MPa (depending on the design) and temperature in the range - 70o - +600o C. They are used in the chemical, petrochemical, food industry, in the branches of mechanical engineering, thermal power engineering. ALFA-STAR company offers stainless steel flanges AISI 304 (08X18H10), AISI 316 (03X17H12M2), 12X18H10T, 10X17H13M2T of the following types:

- DIN and GOST welded flanges are the most common. They are welded to the pipe with two seams and tightened with bolts installed in the mounting holes. To evenly distribute the pressure and achieve tightness, a gasket is placed between the flanges. They are used in pipelines with a pressure of up to 2.5 MPa;

- collar flanges DIN and GOST. They are welded butt-to-butt to the pipe with the end of the conical protrusion of the collar. Provide high tightness and reliability of the connection at a pressure of up to 40 MPa;

- the free flanges are stainless and silumin. They are used complete with a side washer (collar, flanging), the end of which is welded to the end of the pipe. Flanges that move freely through the pipe are tightened with fasteners. They are used on hard-to-reach sections of the pipeline that require frequent repair and maintenance. Silumin flanges are used in areas with a working pressure of up to 1 MPa;

- flange plugs DIN and GOST. Used to block the flow of the working medium;

- flange gaskets DIN and GOST. For low-pressure pipelines, paronite, Teflon, EPDM gaskets are used; steel gaskets are used in conditions of high temperatures and pressure.